CARRY CASES

Why not market your products in professional looking carry cases? Complete with custom made foam inserts to display and protect your products. Inserts can be routed, waterjet, die-cut, or fabricated. They are tailored to fit and bonded into cases of your choice. By selecting the most suitable method of manufacture, for high or low volumes, we ensure the best value for our customers. IMP offers an extensive range of cases, available in many different colours and sizes, which can be screen printed with your logo or product artwork. Internal inserts can be laser etched with part numbers or company logos. Why not customise your protective packaging?

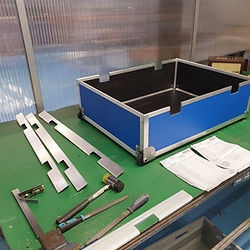

Cases/Inserts/Manufacturing

With multiple methods of manufacturing, there are many options to choose from

Choose your case

Design your cases with ease of use in mind. Choose from hinged or removable.

Laser Etching

Our Laserscript is a must have to enable us to add the finishing touches directly to your products. This could be anything from simple number sequencing to a complex logo design.

Design your Custom Insert

Our two toned foam inserts to accommodate your product in the case of your choice.

Foam Colour and Thickness

We stock our foam in a number of different colour options and can split it to any thickness you requires. Why not make your insert packaging stand out?

Wide Range Of Colours

We stock a number of different colour options. Why not make your case stand out?

Assembly

With a dedicated assembly team, we are able to offer you a complete packaging solution. Items can be fully assembled and delivered directly to your door.

Water Jet

In 2008, IMP invested in two water jet machines. With efficiency and millimetre precision these machines have the ability to cut complex shapes to suit all of your design requirements.

Die Cut

Die cutting is carried out on one of our 3 high speed hydraulic presses. This provides us with the speed and accuracy required to remain extremely competitive. These presses give us the edge, being able to offer the short lead times our customers have come to expect.

CNC Routed Machining

As CNC is an industry standard, IMP has utilized this technology for over 20 years, capable of machining your product from one solid block to a finished item.